Product name: Hex Nuts

Size: M1-M160

Grade: 6, 8, 10, Gr. 2/5/8

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Plain, Black, Zinc Plated, HDG

Norm: DIN934, ISO4032/4033, UNI5587/5588, SAE J995

Sample: Free Samples

Usage: Hexagon nuts are used in a wide range of applications. With fasteners with external threads, such as bolts or studs, use the bolts to pass through the object to be fixed, and then use a wrench to tighten the hex nuts to connect them tightly together, reducing manpower. cost, to play a role in fastening.

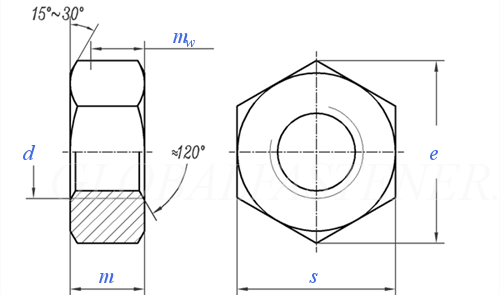

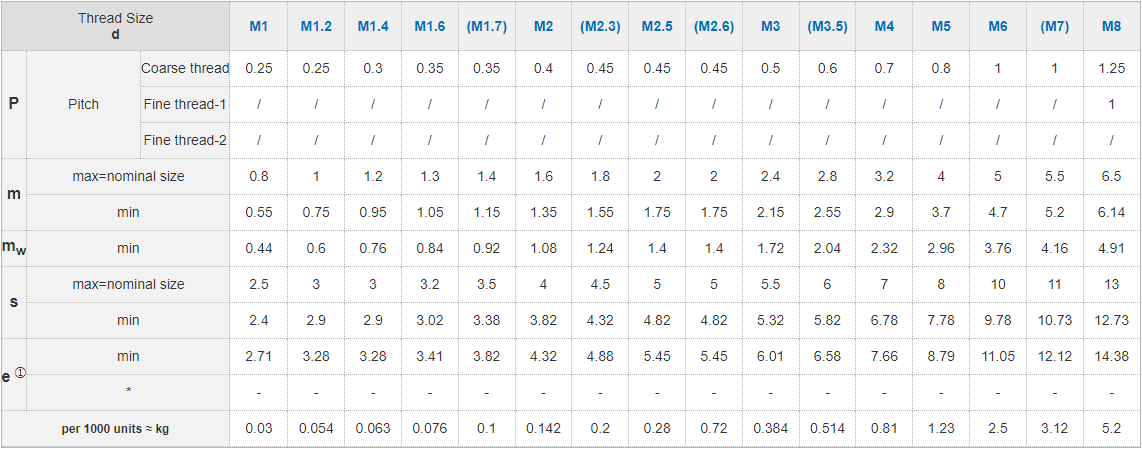

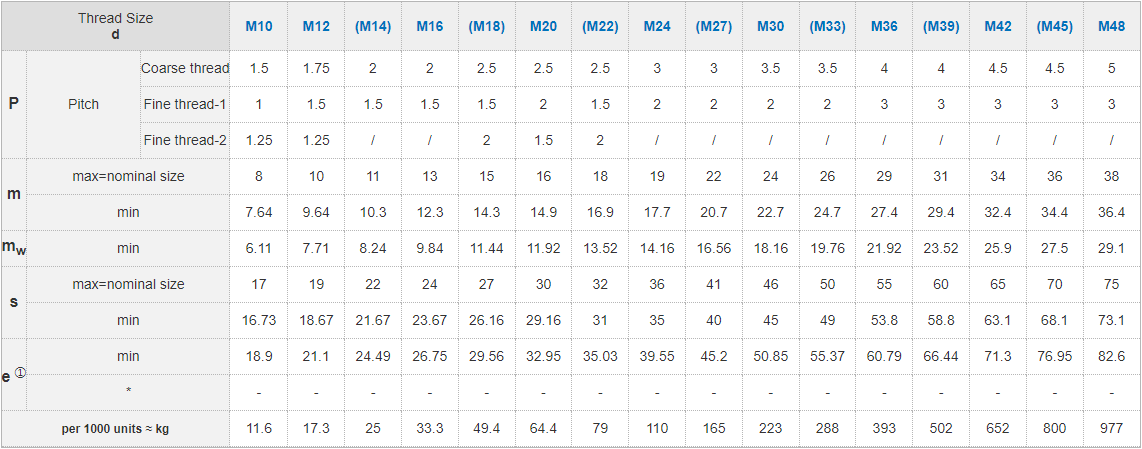

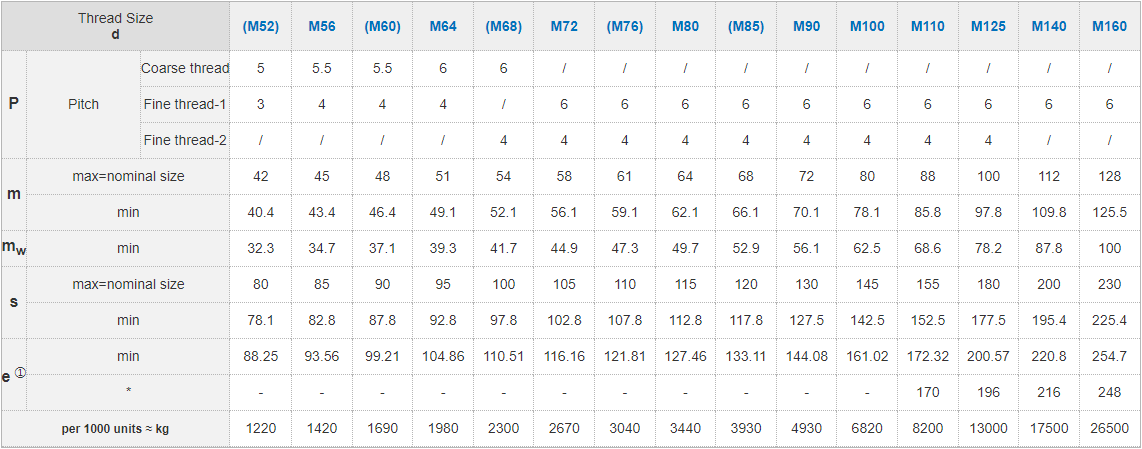

DIN 934 - 1987 Hexagon Nuts With Metric Coarse And Fine Pitch thread, Product Classes A and B

As a standard part, nuts and blind rivets have their own standards. Zonolezer summarises the standards for hex nuts, their distinctions and connections, and their uses. For hexagonal nuts, the commonly used standards are: GB52, GB6170, GB6172 and DIN934. The main differences between them are: the thickness of GB6170 is thicker than that of GB52, GB6172 and DIN934, commonly known as thick nuts. The other is the difference between the opposite sides, the opposite sides of DIN934, GB6170 and GB6172 in the M8 nut series are 13MM smaller than the opposite side 14MM of GB52, and the opposite sides of M10 nuts, DIN934 and GB52 are 17MM. The opposite side of GB6170 and GB6172 should be 1MM larger, M12 nut, DIN934, GB52's opposite side is 19MM larger than GB6170 and GB6172's opposite side 18MM is 1MM larger. For M14 nuts, the opposite side of DIN934 and GB52 is 22MM, which is 1MM larger than the opposite side of GB6170 and GB6172, which is 21MM. The other is the M22 nut. The opposite side of DIN934 and GB52 is 32MM, which is 2MM smaller than the opposite side of GB6170 and GB6172, which is 34MM. (Besides the thickness of GB6170 and GB6172 are the same, the width of the opposite side is exactly the same) The rest of the specifications can be used in general without considering the thickness.

1. Ordinary outer hexagon nut: widely used, characterized by relatively large tightening force, the disadvantage is that there must be enough operating space during installation, and adjustable wrench, open-end wrench or glasses wrench can be used during installation, all of the above wrenches require a large amount of space. operating space.

2. Cylindrical head hexagon nut: It is the most widely used of all screws, because it has a relatively large tightening force, and can be operated with a hexagon wrench. It is very convenient to install and is used in almost all kinds of structures. The appearance is more beautiful and neat. The disadvantage is that the tightening force is slightly lower than the outer hexagon, and the inner hexagon is easily damaged due to repeated use and cannot be disassembled.

3. Pan head hexagon socket nuts: Rarely used in machinery, the mechanical properties are the same as above, and most of them are used in furniture. The main function is to increase the contact surface with wooden materials and increase the ornamental appearance.

4. Headless hexagon socket nuts: must be used in certain structures, such as the jacking wire structure that requires a large jacking force, or the place where the cylindrical head needs to be hidden.

5. Countersunk head hexagon socket nuts: mostly used in power machinery, the main function is the same as the inner hexagon.

6. Nylon lock nut: A nylon rubber ring is embedded in the hexagonal surface to prevent the thread from loosening, and it is used on strong power machinery.

7. Flange nut: It mainly plays the role of increasing the contact surface with the workpiece, and is mostly used in pipes, fasteners and some stamping and casting parts.