Product name: Flat Countersunk Head Square Neck Bolt

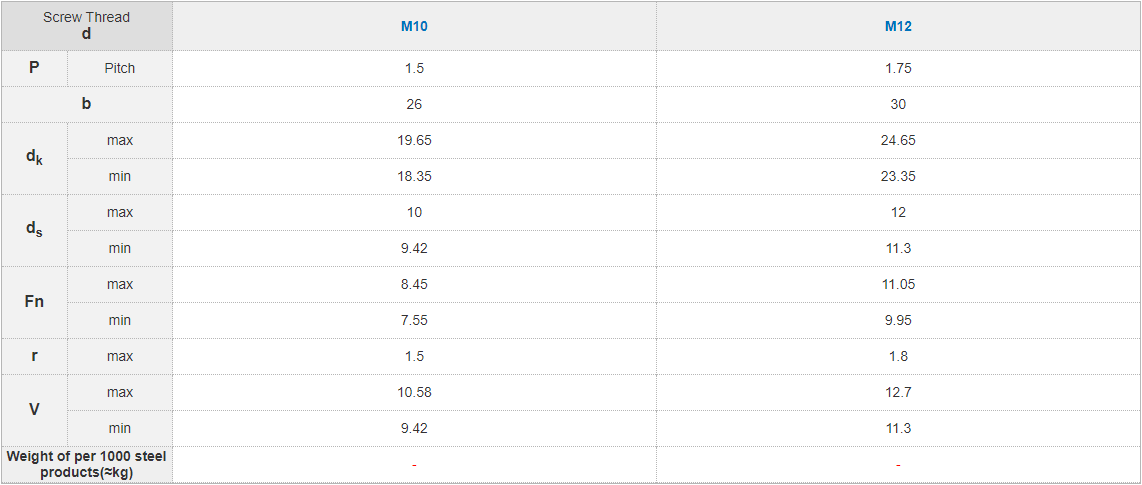

Size: M10-12

Length: 25-300mm or as required

Grade: 4.8 8.8 10.9

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Plain, Black, Zinc Plated, HDG

Standard: DIN608

Certificate: ISO 9001

Sample: Free Samples

Usage: Countersunk square neck bolts rely on other parts to prevent rotation; they can also be used on parts with T-slots to adjust bolt position. Type C square head bolts are often used on relatively rough structures.

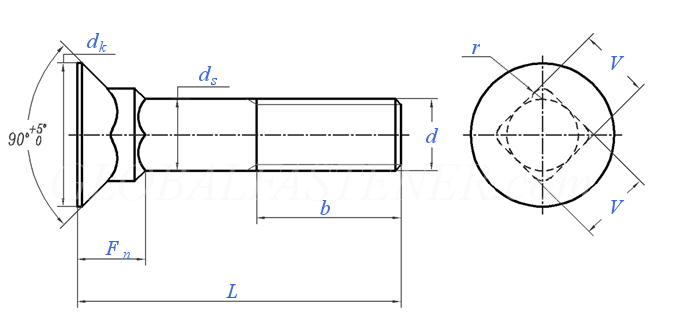

DIN 608 - 2010 Flat Countersunk Head Square Neck Bolts With Short Square

Small screws, big sticks: Zonolezer tells you about countersunk head square neck screws!

Screws play the role of connecting two or more objects and are indispensable in daily life or industrial manufacturing. Countersunk head square neck screw is one of them.

Countersunk head square neck bolts have a 90 degree tapered head and square bottom bolt head very similar to common carriage bolt applications.

The product is galvanized, with beautiful appearance and uniform color. The galvanized layer is passivated into rainbow colors, which can greatly improve its corrosion resistance, and the surface of the head is smooth.

The threading effect is strong, there is no residual burr, the thread is neat and clear, and there is no missing teeth. The groove spacing is neat and even, and the rotation is smooth and fast.

Prevention

1. The taper of the reaming hole should be 90°. It should be guaranteed to be less than 90° and not greater than 90°. This is a key trick.

2. If the thickness of the sheet metal is smaller than the thickness of the head of the countersunk head screw, you can make the screw smaller, or make the reaming hole smaller, and increase the bottom diameter hole, and that's it. It will cause the parts to not be pressed tightly.

3. If there are multiple countersunk screw holes on the part, it should be processed more accurately. Once the drill bit is crooked, it will be ugly to assemble, but as long as the error is not large, it can be completely tightened, because when tightening, if the diameter of the screw is not very large (about 8mm), when there is an error in the hole distance, the screw head will be deformed or tightened .