Manufacturer for Square Nut - Nylon Insert Lock Nuts – Zonolezer Detail:

Product name: Nylon Insert Lock Nuts

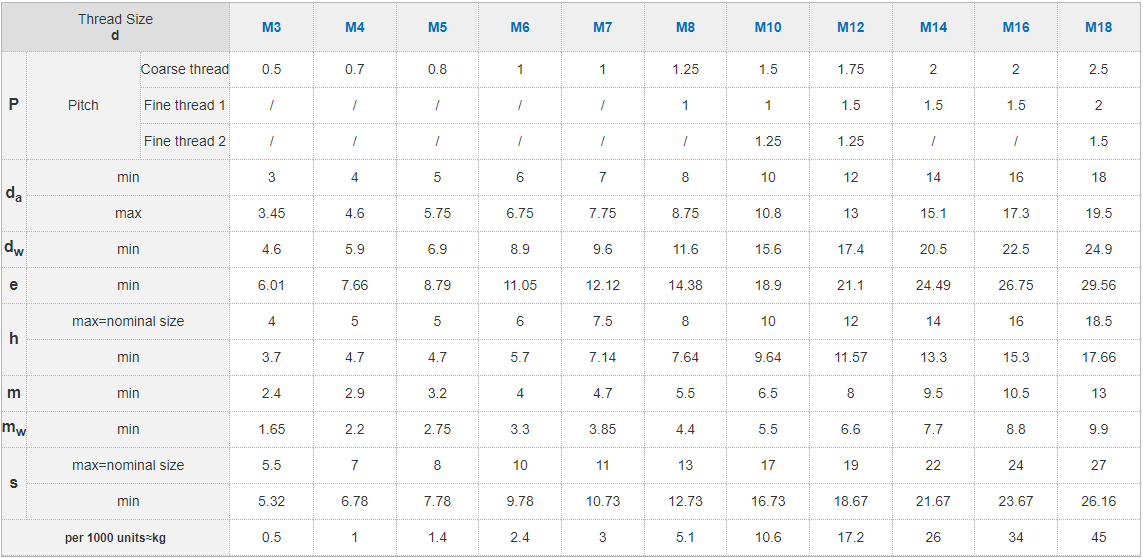

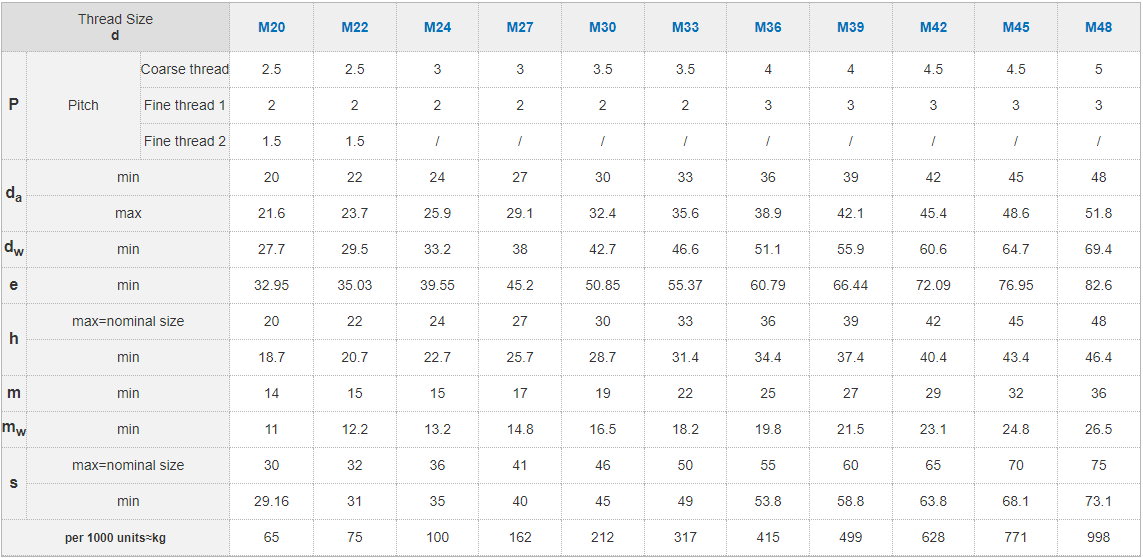

Size: M6-M56

Grade: 6, 8,10, SAE J995 Gr. 2/5/8

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Zinc Plated

Norm: DIN985 DIN982, ASME B18.16.6

Sample: Free Samples

The lock nut is also the nut, which is screwed together with the bolt or screw for fastening parts. It is an original part for all production and processing equipment. The lock nut is the part that tightly connects the mechanical equipment together. , With the help of the threads on the inside, the same specifications and types of lock nuts and screws can be connected together. The following will introduce several methods for preventing lock nuts from slipping. What are the anti-loosening methods of the locking nut?-Zonolezer1. The anti-loosening of the equipment is to use the locking nut stopper to directly limit the relative rotation of the locking nut pair. Such as the application of open pins, serial wires and stop washers. Because the lock nut stopper has no pre-tightening force, the lock nut stopper can only work when the lock nut nut is loosened and returned to the stop position. Therefore, the method of locking the nut does not actually prevent loosening but prevents it from falling. . 2. For riveting punching and anti-loosening, punching, welding, bonding and other methods are applied after tightening, so that the lock nut pair loses the performance of the kinematic pair and the connection becomes an inseparable connection. The disadvantage of this method is that the bolt can only be used once, and the disassembly is very difficult, and the bolt pair needs to be damaged before disassembly. 3. Friction anti-loosening is the most widely used anti-loosening method. This method forms a positive pressure between the lock nut pairs that does not change with the action of external forces, so as to form a friction that can prevent the lock nut pairs from rotating relative to each other. force. This positive pressure can be accomplished by pressing the locknut pair axially or in both directions at the same time. Such as the use of elastic washers, double nuts, self-locking nuts and insert locking nuts. 4. The structure anti-loosening is to apply the self-construction of the lock nut pair, that is, the anti-loosening method of the Down’s lock nut. 5. The edge punching method is used to destroy the thread at the end of the thread after the locking nut is tightened; anaerobic adhesive is generally used for bonding and anti-loosening to apply to the surface of the thread, and the adhesive can be cured by itself after tightening the locking nut. The actual effect of anti-loosening is better. The disadvantage of this method is that the bolt can only be used once, and the disassembly is very difficult, and the bolt pair needs to be destroyed before disassembly.

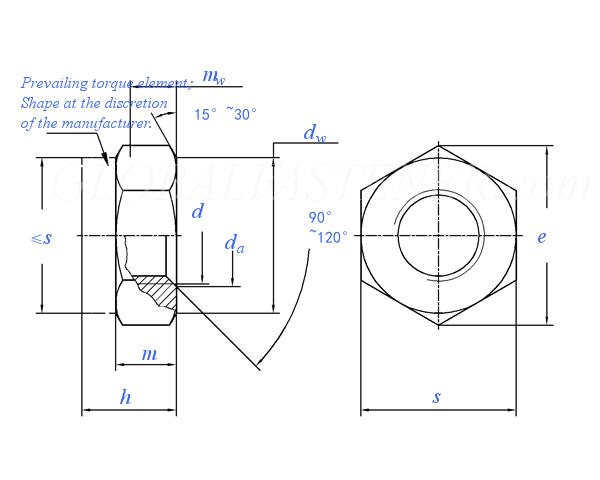

DIN 985 – 1987 Prevailing Torque Type Hexagon Thin Nuts With Non-Metallic Insert

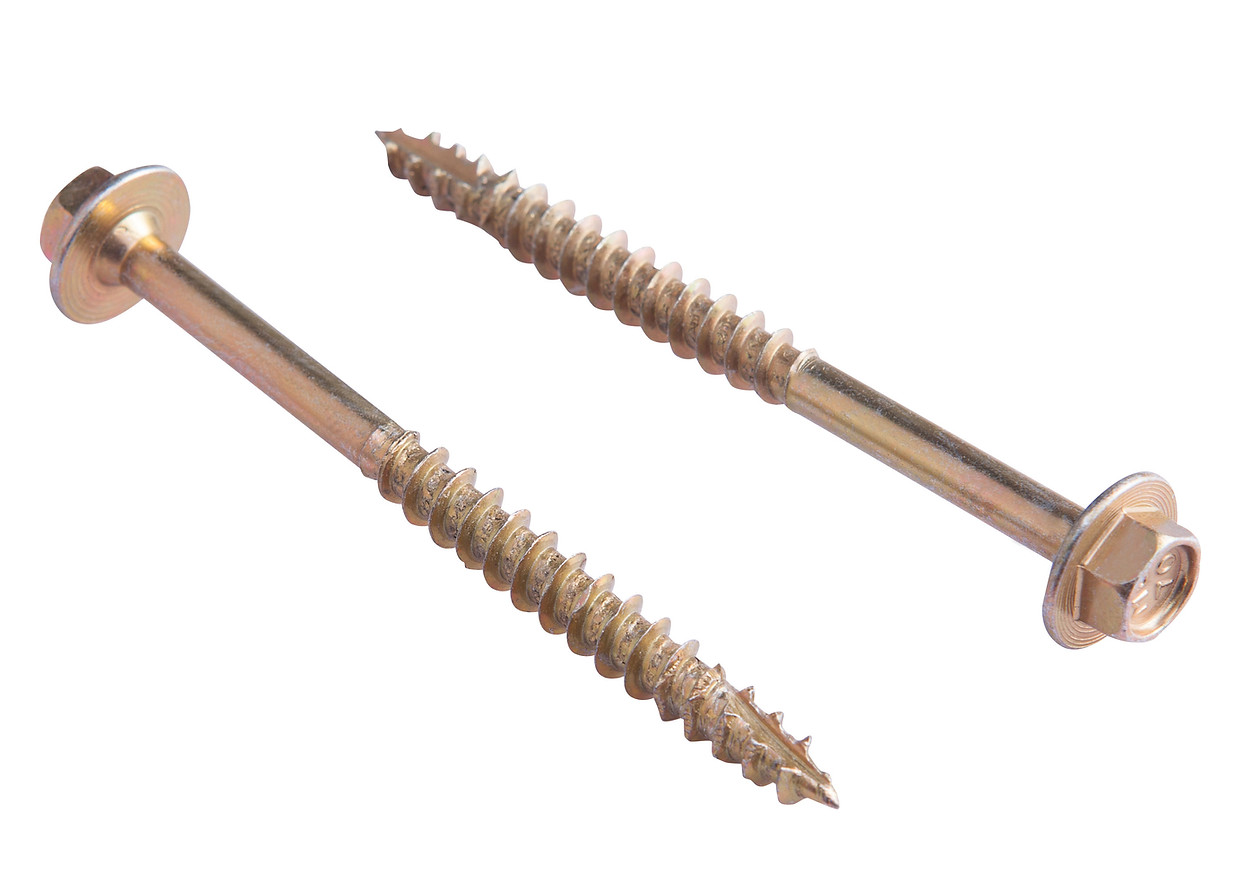

Product detail pictures:

Related Product Guide:

We've been commitment to offer the competitive rate ,outstanding merchandise good quality, too as fast delivery for Manufacturer for Square Nut - Nylon Insert Lock Nuts – Zonolezer, The product will supply to all over the world, such as: United Arab Emirates, Bangladesh, Israel, Our Company policy is "quality first, to be better and stronger, sustainable development" . Our pursuit goals is "for society, customers, employees, partners and enterprises to seek reasonable benefit". We aspirate to do cooperate with all different the auto parts manufacturers, repair shop, auto peer , then create a beautiful future! Thank you for taking time to browse our website and we would welcome any suggestions you may have that can help us to improve our site.

The customer service staff's attitude is very sincere and the reply is timely and very detailed, this is very helpful for our deal,thank you.