Product name: Hex Socket Head Bolt

Size: M3-M100

Length: 10-5000mm or as required

Grade: 4.8 6.8 8.8 10.9 12.9 14.9

Material Steel: Steel/35k/45/40Cr/35Crmo

Surface: Black, Zinc Plated

Standard : DIN912, ASTM A574

Certificate: ISO 9001

Sample: Free Samples

Usage: Steel structures, multi -floor,high -rise steel structure, buildings, industrial buildings, high -way, railway, steel steam,tower,power station and other structure workshop frames

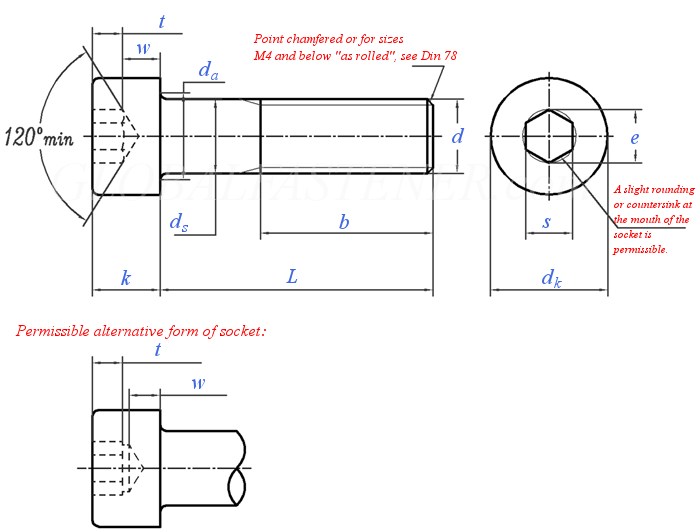

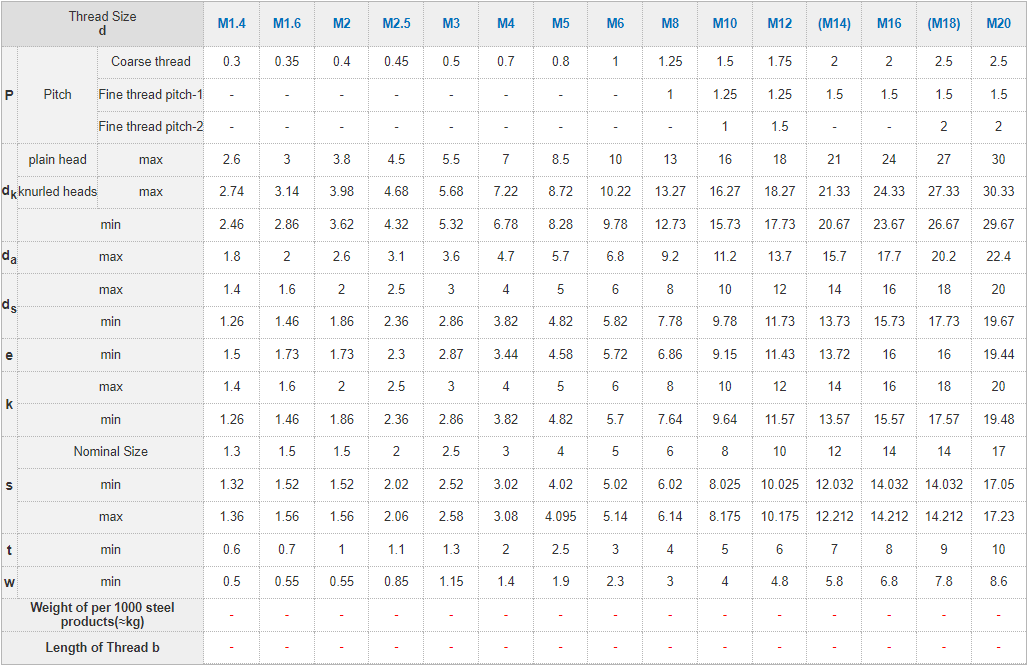

DIN 912 - 1983 Hexagon socket head cap screws

① For size ≤ M4, the point need not be chamfered.

② e min = 1.14 * S min

④ Norminal lengths above 300 mm shall be in 20 mm steps.

⑤ L-b ≥ 3P (P:Coarse thread pitch)

⑥ Material:

a)Steel, Property class: ≤M39: 8.8,10.9,12.9;> M39: as agreed. Standard DIN ISO 898-1

b)Stainless steel, Property class: ≤M20: A2-70,A4-70;> M20≤M39: A2-50, A4-50;≤M39: C3;> M39: as agreed. Standard ISO 3506, DIN 267-11

c)Non-ferrous metal by standard DIN 267-18

Why do many places like to use hexagon socket screws, what is it good for?

The so-called hexagon socket head bolt refers to the cylindrical head with the shape of the hexagon socket, which can also be called the hexagon socket head screw, the hexagon socket head screw and the hexagon socket screw.

Why hexagon, not four or five?

Many people have questions again, why should the design be hexagonal instead of four, five or other shapes? The hexagonal screw can be turned 60° to restore the graphics. If the space is relatively small, the screw can be installed as long as the wrench can be turned 60 degrees, which is the product of compromise between the angle of rotation and the length of the side.

If it is a square, the side length is long enough, but it needs to be twisted 90 degrees to restore the graphic, which is not suitable for small space installation; if it is an octagon or a decagon, the angle of the graphic restoration is small, but the side length of the force is also small. Yes, easy to round.

If it is a screw with odd-numbered sides, the two sides of the wrench are not parallel. In the early days, there were only fork-shaped wrenches, and the wrench head with odd-numbered sides was a trumpet-shaped opening, which did not seem to be suitable for applying force.

hexagon socket hardness and properties

In general, the commonly used hexagon socket head bolts are 4.8 grades, 8.8 grades, 10.9 grades, 12.9 grades and so on. In general, different grades of hexagon socket head bolts are selected according to different needs, so that the performance of the bolts can be more beneficial. Today, Jinshang.com will talk to you about the hardness levels of hexagon socket bolts.

Hardness grade

Hexagon socket head bolts are classified according to the hardness of the screw wire, tensile force, yield strength, etc., that is, the level of the hex socket head bolts, and what level the hex socket head bolts are. Different product materials are required to have different grades of hexagon socket head bolts corresponding to them.

Hexagon socket head bolts are divided into ordinary and high-strength according to the strength of the grade. Ordinary hexagon socket head bolts refer to grade 4.8, and high-strength socket head bolts refer to grades 8.8 and above, including grades 10.9 and 12.9. Grade 12.9 hexagon socket head cap screws generally refer to knurled, natural black hexagon socket head cap screws with oil.

The performance grade of hexagon socket head cap bolts for steel structure connection is divided into more than 10 grades such as 3.6, 4.6, 4.8, 5.6, 6.8, 8.8, 9.8, 10.9, 12.9, etc., of which grades 8.8 and above are collectively referred to as high-strength bolts, and the bolts are made of low carbon Alloy steel or medium carbon steel and heat treatment, the rest are generally called ordinary bolts. The bolt performance grade label consists of two parts of numbers, which represent the nominal tensile strength value and yield ratio of the bolt material respectively.

Performance class

The bolt performance grade label consists of two parts of numbers, which represent the nominal tensile strength value and yield ratio of the bolt material respectively.

Bolts of performance class 4.6 mean:

1. The nominal tensile strength of the bolt material reaches 400MPa;

2. The yield strength ratio of the bolt material is 0.6; the nominal yield strength of the bolt material is 400×0.6=240MPa.

Performance level 10.9 high-strength bolts, after heat treatment, can reach:

1. The nominal tensile strength of the bolt material reaches 1000MPa;

2. The yield strength ratio of the bolt material is 0.9; the nominal yield strength of the bolt material is 1000×0.9=900MPa.

The meaning of the performance grade of hexagon socket head bolts is an international standard. Bolts of the same performance grade, regardless of the difference in material and origin, have the same performance, and only the performance grade can be selected in the design.

Different grades have different prices on the market. Generally, the price of high-strength socket head cap bolts is definitely much higher than that of ordinary socket head cap bolts. In the market, the most commonly used are 4.8, 8.8, 10.9, and 12.9. Zonolezer currently offers socket head cap screws in grades4.8,6.8,8.8, 10.9, 12.9, and 14.9.

Advantages of using hexagon socket bolts

1. Can withstand larger loads.

It has six force-bearing surfaces, which is more resistant to screwing than flat-blade screws and cross-shaped screws with only two surfaces.

2. can be buried in use.

That is to say, the whole nut is sunk into the workpiece, which can keep the surface of the workpiece smooth and beautiful.

GIF cover

3. Easy to install.

Compared with the outer hexagon screw, the inner hexagon is suitable for more assembly occasions, especially in narrow occasions, so it is very convenient to assemble and maintain, and it is also convenient to debug.

4. Not easy to disassemble.

The tools we usually use are adjustable wrenches, screwdrivers and dead wrenches, etc., and special wrenches must be used to remove hexagon socket bolts. Therefore, it is not easy for ordinary people to disassemble. Of course, if you are competitive, you can design all kinds of bizarre structures. The question is whether the s